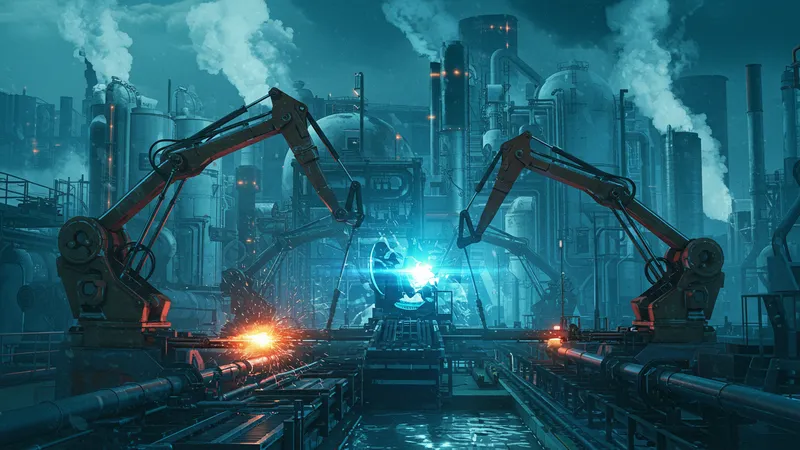

What if we told you that the machinery powering modern industries holds a secret that could revolutionize the way we manufacture, build, and even clean our cities? The hidden force of hydraulic machinery is the quiet giant shaping our world.

In today’s fast-paced industrial landscape, understanding the power of hydraulics is more crucial than ever. With environmental impacts and efficiency demands rising, companies are harnessing this ancient technology for cutting edge applications. But what secrets does this powerhouse technology hold that could disrupt industry norms?

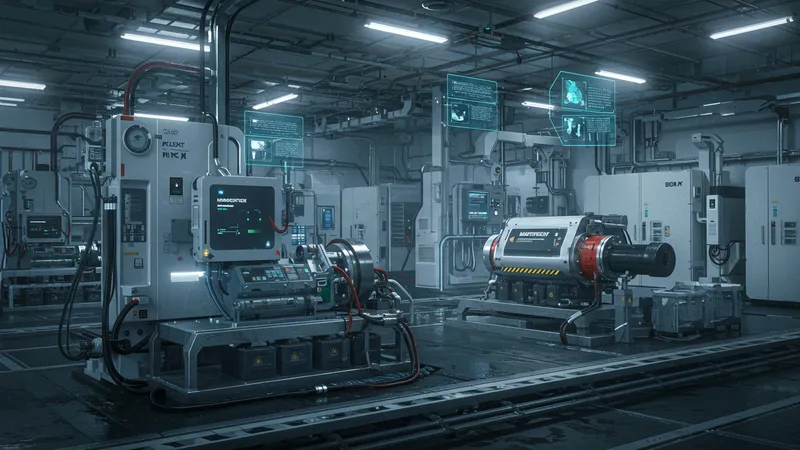

While many know that hydraulic machinery plays a pivotal role in construction and manufacturing, few realize that the latest innovations are being driven by surprising technologies. One such innovation involves the synergistic use of artificial intelligence with hydraulic systems, boosting precision and cutting operational costs astronomically. But that’s not even the wildest part…

The hidden adaptability of hydraulic systems is mind-boggling. One development utilizes nanotechnology to enhance fluid dynamics, creating systems that are faster, more efficient, and incredibly cost-effective. Imagine machines potentially producing zero waste while consuming half the energy—they're closer to reality than you might believe. But once you learn what’s coming next, it’ll challenge everything you thought you knew…

What happens next shocked even the experts, as industry leaders uncover and leverage unexpected facets of hydraulic technology. Could the next major leap not just optimize, but revolutionize manufacturing? Let’s dive deeper into these groundbreaking revelations and what they mean for the future of industry…

Hydraulic systems are being reinvented with remarkable efficiency breakthroughs. Engineers are exploring the inclusion of biodegradable hydraulic fluids, which not only smallen the environmental footprint but also promise enhanced thermal stability. The ironic twist? Previously seen as a disadvantage, this fluid type drastically reduces maintenance needs. But there's a fascinating aspect yet to uncover…

Pressure-compensated pumps are another revelation in the hydraulic domain, becoming a highly sought-after solution. These pumps automatically adjust flow rates and pressures to meet specific load demands, resulting in significant energy savings. The technology not only streamlines production but also speaks to sustainability. What you read next might change how you see pump technology forever.

Have you heard about adaptable hybrid systems? By merging pneumatic systems with hydraulic power, industries witness improved precision and increased performance flexibility. This game-changer is being embraced by automakers and heavy machinery manufacturers alike. But there’s one more twist that takes adaptability to new heights…

Perhaps most intriguingly, sensor-driven real-time monitoring systems are being integrated into hydraulic machinery. These systems preempt issues before escalation, saving not just money but valuable time. Imagine a world where breakdowns are virtually eliminated. The continual evolution of hydraulics is laying the groundwork for an industrial future like no other…

The rise of electric-driven hydraulic pumps is fundamentally altering the equipment landscape. These battery-operated systems shine in areas where traditional diesel power lags, offering quieter, more precise operations without sacrificing power. Yet, the potential environmental impact reduction is perhaps the most astonishing factor. But there's more than meets the eye…

Inductors are being blended into hydraulic systems to provide added control and predictability in machinery operations. Initially overlooked, these components ensure a more fluid response to pressure changes, boosting the overall potential of hydraulic applications. The full transformative impact is still unfolding, but the results are promising.

Emerging telemetry systems are another pivot in hydraulic development, granting instant access to system diagnostics and enabling remote controls via smartphones and computers. This innovation not only simplifies complex tasks but also lowers operational costs and enhances safety. What comes next will shed new light on telemetric advancements…

Parallelly, explorative research into magnetic filtration of hydraulic fluids shows promising advancements, capturing previously unbeatable contaminants. By maintaining cleaner systems, the efficiency and longevity of machinery are notably improved. These evolutionary steps speak volumes about the untapped capabilities of hydraulics in reshaping industries worldwide…

Hydraulic power has often been maligned for its ecological effects, but who knew its potential for positive change? New developments have made it possible for these systems to leverage renewable energy sources tidily. Imagine harvesting solar or wind energy to operate hydraulic machinery efficiently. But wait until you discover the scale of this impact…

Eco-friendly hydraulic solutions are rising stars, with advanced systems designed for minimal fluid leakage and maximum recapture efficiency. Even sealed hydraulic systems are being considered to prevent contamination and promote cleaner operations in every field. The possibilities here are far-reaching and transformative.

Another highlight is the rise of biodegradable oils in hydraulic systems, creating eco-conscious solutions that perform outstandingly within various temperature and pressure conditions. These green alternatives are rapidly gaining traction among eco-focused businesses. Yet, the story doesn’t end here, quite the contrary…

Furthermore, hydraulic advancements enable reuse of materials, drastically minimizing industrial waste. Companies adopting this practice quickly achieve sustainability benchmarks while driving growth. As these systems continue their eco-friendly evolution, one key revelation remains to be explored—what happens when technology truly aligns with nature…

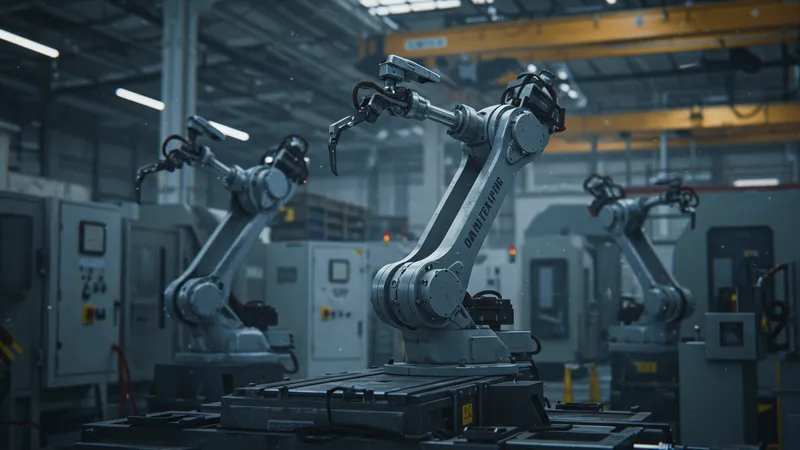

The integration of hydraulics within robotics is redefining what machines can achieve. Hydraulics for robots are a perfect match, providing unmatched dexterity and immense strength while keeping robots compact and efficient. This synergy might just be a stepping stone to a new industrial age. But that's just scratching the surface…

Highly flexible hydraulic joints are now making robots more adaptable and capable of complex maneuvers, unheard of with rigid mechanics. Industries are rapidly adopting these agile machines to enhance production rates and tackle intricate tasks effortlessly. The surprising frontier of this tech appears even more transformative.

Surging ahead, the robots powered by hydraulic systems offer greater precision in laboratory settings and medical applications, showcasing their versatility across diverse fields. These tools combine strength and finesse that conventional robotics had long strived for. Yet, it’s the cost-saving implications that catch everybody off-guard.

The rapid development trajectory promises such collaboration is only in its infancy. Enhanced AI integration is pushing these hydraulically driven robots beyond ordinary limits. Industry specialists expect a paradigm shift as autonomous hydraulic robots lead the charge toward unprecedented industrial applications…

Not just confined to Earth, hydraulic technology ventures into the aerospace arena, revolutionizing how we think about flight and space exploration efficiency. These systems now underpin everything from landing gear mechanisms to jet engine components, yielding surprising efficiencies. Let’s explore the unanticipated benefits…

In aerospace, weight is critical. Engineers ingeniously employ lightweight materials alongside hydraulic power to optimize aircraft performance. The results are strikingly efficient planes boasting extended range and aerodynamics. What unfolds from this engineering marvel will astound you.

Hydraulic systems have also pioneered greater safety and reliability in avionics, with enhanced precision—saving thousands of lives by mitigating risks in adverse conditions. The newfound robustness and operational assurance have been game-changers that went beyond expectations. Yet, a revolutionary innovation still waits to be explored…

Breakthroughs in hydraulic-driven aircraft systems aren't solely limited to typical aerodynamics. Close partnerships with rocketry sectors suggest enormous potential for hydraulic systems in launching, maneuvering, and even landing spacecraft. These bold advancements unfold a horizon of new exploratory ambitions, pushing our global journey further…

In the realm of mining, hydraulics play an unsung yet pivotal role—quietly empowering massive machinery to unearth treasures from beneath the earth's surface daily. Sophisticated hydraulic machinery now emerges leading from the front, driving sustainable mining practices. What else promises to refine this field's operations?

Modern hydraulic drills and excavation rigs demonstrate heightened power and precision to tackle even the obstinate geological formations, vastly minimizing energy consumption and operational time. Industries remain stunned by such impactful outcomes. But here lies a more interesting twist unfolding in real-time…

The stunning capabilities don’t stop there. Cutting-edge hydraulic systems now support underwater mining, reaching untouched resources previously deemed unreachable. These developments turn theoretical possibilities into tangible reality, with implications reverberating across global resource management.

The latest buzz in hydraulic mining technology reaches enterprising expansions into underwater exploration, marking the dawn of a new treasure hunt. Safer, less intrusive operations are being designed to preserve, protect, and yet yield huge gains, balancing our resource needs with ecological preservation…

In medicine, hydraulics has empowered numerous life-saving technologies, but how far do these applications truly reach? From wheelchairs to advanced surgical instruments, hydraulic systems are quietly raising the bar for healthcare standards around the world. But hidden potentials still linger…

Hydraulic lift systems offer increased autonomy for mobility aids, granting users greater freedom and dignity. This advancement has revolutionized patient care, combating the challenges faced by traditional electronic lift systems. Yet new innovations are paving unparalleled paths forward…

Surgical precision is also reaching new heights due to hydraulically assisted surgical robots, offering doctors enhanced control and precision even in minimally invasive procedures. Lives are saved, patient recovery speeds up, and surgical scarring reduces with these technologies. But this is just the beginning…

Exoskeletal systems break new ground, enhancing physical therapy and rehabilitation results exponentially. Harnessing hydraulic assistance, they speed up recovery timelines for injured patients immensely. As hydraulic machinery continues to redefine healthcare, watch this space for industry-shaking developments just around the corner…

As environmental consciousness accelerates, hydraulics finds itself an ally in green innovations. But what solutions do these unique systems offer in reducing industry’s ecological footprint? Surprisingly, ground-breaking strides are paving the way toward greener and cleaner practices, but the story runs deeper…

Next-level recycling plants are utilizing hydraulic presses to compact materials more efficiently, optimizing space and reducing energy consumption. These modern presses operate with finesse, offering radical waste management solutions. Let’s dissect further and unveil new horizons ahead…

Interestingly, in agricultural spheres, hydraulic machinery allows farms to operate mechanically with reduced environmental impact, ensuring crop yields remain unaffected by harmful externalities. Innovations here hold tantalizing possibilities for global food security. The narrative doesn’t merely end here.

Hydraulic technology’s eco-footprint keeps shrinking with the advent of fugitive emissions capture systems improving industrial emissions integrity. These systems ensure minimal leakage and support stringent eco-compliance levels contributing beyond traditional expectations. The synergy between ecology and hydraulics sets the stage for a groundbreaking alliance…

Hydraulic systems in transportation aren’t just about traditional engineering marvels; they prove pivotal in advancing vehicular efficiency, achieving a seamless marriage with cutting-edge technology. Look deeper into the impact, and discover uncharted possibilities shadowing routine perceptions…

Hybrid hydraulic vehicles reveal themselves as contenders against long-standing combustion engines, pairing hydraulic systems with electric drivetrains to create greener, more resilient transportation solutions—fuelling debates for a sustainable, innovative future. This story doesn’t merely end here, however.

Efforts in bus and logistics industries to implement regenerative hydraulic braking systems underscore the need for efficient energy use, dramatically decreasing carbon emissions and creating echoes of impactful innovation. Attention-seeking advancements press forward with further implications to digest…

Considerations of maritime transport acknowledge substantial hydraulic innovations too, revealing new vessel propulsion, cargo loading systems equipped with hydraulic control, and energy-efficient navigational solutions rising. It seems the confluence of hydraulic technology offers limitless realization across transportation corridors.

In construction, hydraulics is forging paths where imagination comes alive, helming projects that reshape skylines. From towering cranes to earth-moving machines, hydraulics enhances scale and efficiency. Dive into development narratives, unearth promising expansions yet unknown…

Sky-high ambitions anchor on novel hydraulic lifts, which now negotiate towering heights at speeds previously unreachable, transforming urban construction. With bolder structures come grander challenges met by agile machinery—an engineering marvel that surprises constantly.

Paving new paradigms within precision engineering lies hydraulic drilling methodologies ensuring immaculate construction finishes, underpinning skyscrapers, and dynamic cityscapes. But behind this progression, thrilling revelations continue to peak industry interest.

The backbone solidifies further: hydraulic machinery’s role in additive manufacturing grows, promising customizable build solutions, with 3D printing harnessing hydraulic prowess to redefine architectural possibilities. The industrial melody of new futures orchestrates before us spectacularly…

In marine engineering, hydraulics anchor astonishing endeavors at sea—vessels whisper of engineering prowess where fluid dynamics operate silently. Unveil unsung innovations where hydraulic power reverberates intimately among ocean waves…

Hydraulic anchor systems accurately position vessels, challenging volatile sea conditions without losing hold. Maritime engineers impress by orchestrating docking precision to safeguard operations, leaving the sea less warring, more charmed by innovation, proving that possibilities are boundless…

Hydraulic winches demonstrate tremendous power at sea, manipulating weights seamlessly with minimal human intervention. The fishing industry prospers under such systems, broadening horizons unapologetically where maritime technology sails bravely to new fathoms.

The revolution opens new windows with hydraulic-assisted robotic diving gear solving underwater mysteries efficiently. Underwater minerals, shipwrecked treasures beckon, as curiosity leads daring adventurers further into ocean explorations beneath hydraulic ingenuity's charm.

A mundane yet profound truth—hydraulics surrounds us in daily experiences unnoticed. Comprehending hydraulic systems’ nuances—elevators, braking systems in cars, or even simple tools—is an adventure unfolding untapped promises hidden in plain sight…

Did you know captivating elevator hydraulics effortlessly transport countless lives skyward, forming essential urban arteries—including vast apartments, shopping complexes' vertical networks? Their seamless operation epitomizes overlooked reliance on ingenuity marvels.

Wonder at household appliances wielding hydraulic principles, sustaining unprecedented conveniences. Dishwashers wonder involuntarily observe hydraulic prowess, simplifying life burdens silently with revolutionary efficiencies. Dig deeper—hidden veil reveals expanding influences.

Across campuses, unnoticed hydraulic gym equipment shapes fitness pursuits, urging limits. Unseen inspirations resurface daily—linked to hydraulic mastery narrating normalized blend with modern lifestyles, waking unspoken truths of fluid societal harmony poised before discovery…

As we peel back the layers of hydraulic machinery’s intricacies, the image surfaces clearer: a technology that powers our industries, homes, health, and hobbies, sometimes in astonishing ways. The last frontier waits undiscovered, pressing forward with bold urges for innovative spin on the ordinary. Let us lean into action—share this enlightening journey with others, bookmark insights for future explorations, and welcome the transformations hydraulic potentials promise to unveil!