Imagine a world where every packaging machine could revolutionize your production line, yet many manufacturers are still making costly mistakes. What if the key to streamlining your operations was simpler than you believed?

In today's fast-paced market, grasping the intricacies of packaging machines is crucial. As automation advances, savvy businesses need to know which features can truly make or break their ROI.

Did you know that many companies fail to utilize packaging machines to their full potential, losing thousands in inefficiencies? In an industry where time is money, ignoring the capabilities of modern packaging equipment can sink your entire budget. It might seem enough to pick a machine based on speed and price, but other overlooked elements, such as flexibility and maintenance costs, can make a world of difference. But that’s not even the wildest part...

Even reputable brands occasionally mislead with their machine specs, causing well-meaning businesses to invest in systems that don't fit their needs. Industry insiders warn us about the common pitfalls and secret tactics some manufacturers use to mask true performance metrics. However, the tricks don't stop there, as even the savviest of us can be blindsided. But that’s not even the wildest part...

What happens next shocked even the experts. Unseen flaws and unexpected advantages are lurking behind every conveyor belt and sealing clamshell. Are you curious to discover what makes these machines tick and how you can leverage them to catapult your business forward? Trust me, you’ll want to see this...

When it comes to packaging machines, upfront costs are just the tip of the iceberg. Many businesses are startled to discover that maintenance and repair fees can quietly add thousands to annual expenses. An unexpected breakdown or parts replacement could stall operations for days, disrupting the entire production line. What you read next might change how you see this forever.

Operational downtime is not usually discussed openly, yet it’s a silent profit-killer. Statistics show businesses can lose up to 20% of their production time due to machine malfunctions. Proactive maintenance and understanding machine intricacies can help reduce these incidents. But there’s one more twist you haven't considered.

The choice of suppliers also plays a significant role in ongoing costs. Lesser-known brands might offer cheaper prices, but often, such savings comes at the expense of machine reliability and customer support. Learning to distinguish quality from mere marketing is a skill worth developing. What comes next might surprise even seasoned manufacturers.

Moreover, there are hidden energy consumption costs that weigh heavily on the long-term budget. Machines promising high output often require significant power, leading to inflated utility bills. The efficiency of a packaging machine doesn’t just mean faster production but smarter energy use as well. And that’s not all—wait until you uncover how innovation further changes the playing field.

Not all packaging machines are created equal, and identifying quality involves more than just specs on paper. The build quality of machinery dictates its life span and efficiency. Inspecting materials used, particularly stress-bearing parts, can reveal more about potential longevity than catalog promises. But there's more to uncover.

Testing conditions can also betray the true quality of a machine. Experts suggest running extensive field tests to simulate real-world conditions before finalizing a purchase. Adjusting your focus to performance under stress will bring hidden strengths and weaknesses to light. But wait, isn’t there a surprising twist?

Additionally, some machines might offer incredible efficiency but at the cost of operational flexibility. As production needs evolve, the ability to adapt packaging machines without extensive retooling becomes vital. Seek out models that offer modular designs or easy switch-outs, an underrated aspect that can save time and money. The next revelation beats the rest by far.

Finally, a critical yet often neglected factor is the operational ease. Complex interfaces that require too much human intervention can lead to operator errors and increased training burdens. Machines that simplify operations with user-friendly interfaces ensure that productivity remains high. What you discover next turns the notion of quality completely on its head.

Environmentally conscious manufacturing is no longer optional—it’s a vital component of business strategy. Packaging machines that reduce waste and optimize material usage do not just cut costs but also enhance brand reputation among eco-aware consumers. But hold on, there’s a shocking aspect to this narrative.

Some businesses are blindsided by the false sense of security in eco-labels. Not all green certifications have robust criteria or consistent oversight. Knowing which certifications to trust can play a significant role in brand credibility. But that’s not all, what’s next could redefine your approach.

Beyond certifications, the machine’s actual efficiency in resource use needs consideration. Advanced machines use precision technologies to ensure minimal raw material wastage. Consider upgrading to machines with built-in sensors that fine-tune the process for maximal efficiency. What’s coming next is an entirely different perspective.

Yet, the real game-changer is the shift to renewable energy-powered machines. Innovative manufacturers are paving the way with solar-integrated systems, reducing the environmental footprint significantly. These sustainable choices can also translate into lucrative green tax incentives. And still, there’s more to explore in the next reveal that gets to the core of this transformation.

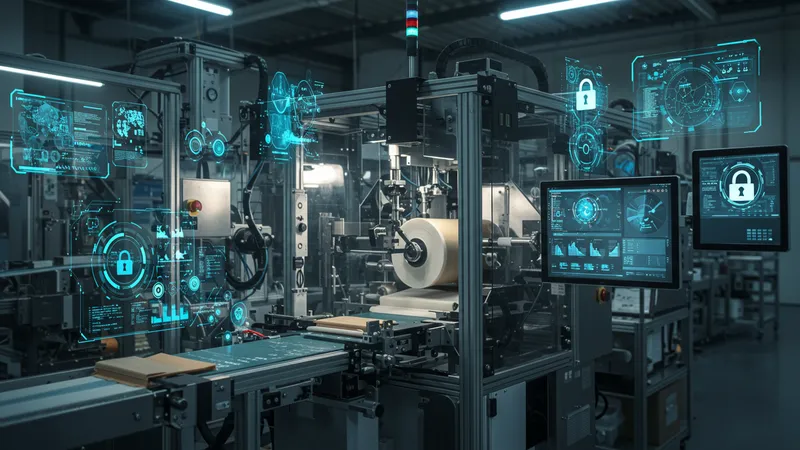

The landscape of packaging machinery is undergoing a paradigmatic shift thanks to automation. AI-enabled machines can now self-diagnose and optimize production in ways unimaginable just a few years ago. A simple software update can transform machine capabilities overnight. Curious about how deep this rabbit hole goes?

As automation grows, so does the importance of cybersecurity. Hackers could exploit weak points in system networks, causing disruptions. Hence, opting for machines that prioritize security with robust firewalls is critical. But that’s just the start of a tech-driven journey.

Aside from better security, automation introduces unparalleled accuracy in packaging. Machines can handle minuscule deviations with precision, thereby reducing product spoilage and returns. But it doesn't stop there—the impact extends beyond just efficiency.

The revolution doesn't merely reside in the machines; it resonates through the supply chain, changing inventory strategies and logistics. Automated machines provide real-time data, helping businesses pivot strategies dynamically. Prepare for shocking insights as we dive deeper into the unstoppable drive of automation.

Smart data is a buzzword that has real implications for packaging machine users. It helps track metrics like machine efficiency, material usage, and production rates seamlessly. Everything you’ve heard about this is just the beginning.

The fusion of data analytics with machine performance has companies rethinking their operational strategies. Machines now provide insights on wear-and-tear to preempt maintenance schedules, greatly reducing unexpected downtimes. What you'll learn next flips conventional wisdom on its head.

Leveraging data also means predictive capabilities. Businesses can now foresee demand fluctuations, allowing for better planning and resource allocation. In a world where margins matter, each added percentage of efficiency translates into bigger profits. But the surprises don't end here.

Advanced telemetry isn't merely a tool; it's transforming competition. Companies staying ahead compute every variable in their operations to extract maximum value, while those lagging behind might find themselves outpaced. Ready to unlock even more groundbreaking insights? Let’s continue!

The journey through packaging machines presents pitfalls, and steering clear of these can save substantial investments. One common mistake is underestimating installation complexity and costs, which could balloon budgets and delay operations. But experts have discovered pitfalls far greater than these.

Choosing machines based on aggressive marketing and unverified performance claims often leads to buyer’s remorse. It’s crucial to demand proof through case studies and testimonials, not glossy brochures. Still, this isn’t the most unexpected blunder companies make.

Under-utilization due to staff resistance or lack of training is another issue that quietly eats away potential returns. Investing in comprehensive training can turn hesitations into wholehearted adoption. Yet, the most cunning oversight remains to be unveiled.

Decisions driven purely by initial pricing rather than long-term value are perilous. Wise investments factor in scalability, quality, and post-sale support. Navigating through the landscape of purchasing mistakes, each error presents a lesson to be embraced. Wait until you uncover the ultimate lesson learned.

The packaging machinery industry is evolving with lightning speed, influenced by technology and environmental pressures. Predicting these trends could position companies at the forefront of innovation. And while some trends are clear, others are emerging under the radar.

One undeniable future trend is increased machine-human collaboration, with machines taking over repetitive tasks and humans focusing on high-level decision-making. The repercussions of these changes are profound and unpredictable.

With environmental consciousness, biodegradable packaging solutions embedded into machines are gaining traction. This dual function eliminates separate processing steps, enhancing efficiency. Yet, the most transformative trend is still under wraps.

The rise of decentralized production, driven by compact, efficient machines that allow flexible, localized manufacturing, stands to revolutionize industry paradigms. With these machines, companies can adapt rapidly to localized demands, shortening supply chains abruptly. Discover how these trends could propel your business into the future with ease.

Deciding on the right packaging machinery involves a matrix of considerations that climb beyond basic functionality and cost. Identifying specific needs such as packaging type, volume, and speed is a great starting point, but this barely scratches the surface.

It’s vital to see beyond the layers of negotiations. Take into account potential upgrades and service agreements, which can vastly influence the total cost of ownership and machine lifecycle. However, this is only the framework of a more complex decision-making process.

The interplay between engineering quality and customer support cannot be underestimated. Hire technical advisors if necessary, as their expertise could save months of frustration. Yet, another dimension remains outstanding and shifts perspective completely.

Finally, understanding market conditions can shift the scales. Economic cycles, pricing trends, and availability affect buying decisions more than personal preference. Negotiate wisely with this knowledge, unlocking a significant competitive advantage. Discover next how strategic foresight in buying pays off in unimaginable ways.

To truly maximize the investment in packaging machinery, consistent strategy alignment and advanced planning are indispensable. Regular evaluations of productivity benchmarks ensure machines deliver expected returns over time. Surprisingly, this isn't where smart investments end.

Retrofitting or upgrading existing machinery can often accomplish more than outright replacement—an added boost to functionality without the heavy cost. That’s only the beginning of profit-maximizing strategies.

Another overlooked gem is software updates that enhance machine intelligence and interconnectivity. Many manufacturers often skip checking for updates that could enhance precision and save resources. But the most astonishing investment tactic is yet to be explored.

A shift in focus towards energy-efficient operations results in immediate cost savings, with potential for green subsidies and tax offsets. Optimizing investment, therefore, combines technology improvements with sustainable innovations. And there’s more potential ahead, waiting to revolutionize your outlook even further.

The relentless march of technology is transforming packaging at its core. Integrating IoT (Internet of Things) into machines turns data collection into an art form, enabling real-time decisions and substantial efficiency gains. But there are still layers to be unraveled.

Robotics are fast becoming the backbone of automation in packaging processes. Beyond simply replacing human labor, their precision and consistency drastically reduce waste, delivering perfected output. Yet there's an unexpected twist to robotics that hasn't been widely considered.

Artificial Intelligence is not just about automation; it’s extending machine learning into predictive maintenance, flagging potential issues before they occur. This proactive stance is taking risk management to new heights. Still, the most staggering element of this integration is next in line.

As supply chains become more interconnected, blockchain systems are revolutionizing traceability, promoting transparency from raw material to finished product. This transparency builds trust and opens doors to new market opportunities. What you discover here might redefine how you look at the potential of future technologies.

Creating a packaging strategy that withstands the test of time revolves around embracing technological advancements and sustainability. This ensures businesses not only remain competitive but become leaders in innovation. What comes next is crucial to crafting your future-proof blueprint.

Strategic alliances with pioneering technology providers give businesses a razor’s edge, facilitating access to cutting-edge solutions ahead of the competition. Keeping this network strong and dynamic is part of the broader strategy.

A forward-thinking approach includes building adaptability into machine selection. Machines capable of handling new materials or packaging designs without re-engineering investments are invaluable. This foresight transforms challenges into opportunities at the drop of a hat.

Furthermore, sustainability should be integral to strategy and not a standalone initiative. Establishing eco-friendly operations fosters goodwill and loyalty, differentiating your brand within hyper-competitive landscapes. The insights here blend technology with vision for an unbeatable formula. So what’s the game plan moving forward?

Many businesses have doubled or trebled productivity simply by choosing the right packaging machines and strategy. One food manufacturer leveraged precision automation and reduced waste by 50%, boosting profits dramatically. But why stop here? Discover more unexpected successes.

Another company discovered the power of IoT, which allowed equipment to self-optimize in real-time, injecting unparalleled efficiency. This adaptive feature turned routine operations into competitive advantages, leaving competitors scrambling. This is only one dimension of success.

A third case revealed how a beverage firm shifted to biodegradable packaging without compromising on production speed. The positive environmental footprint boosted brand image and customer loyalty. Yet, the most surprising triumph is on the next line.

Finally, a household goods manufacturer integrated blockchain for complete product traceability. Increased transparency led to greater trust among buyers, amplifying sales channels. Each success story redefines possibilities and invites exploration into areas previously deemed unachievable. What invites your breakthrough journey?

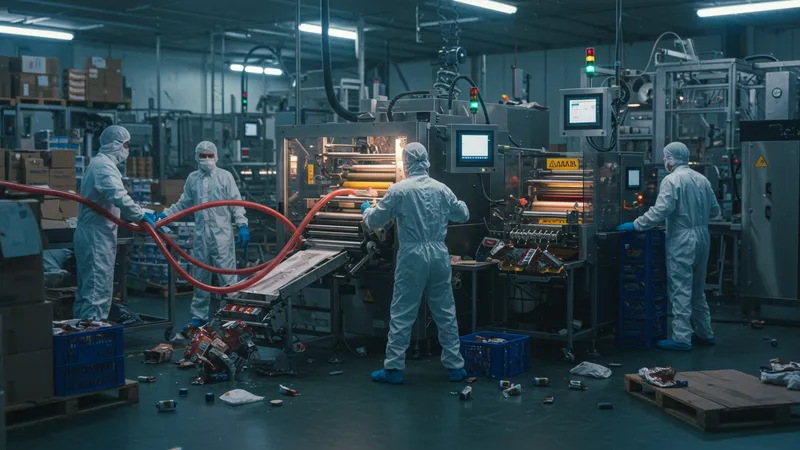

Common pitfalls, if not addressed, could derail the smooth running of packaging machines and obliterate planned ROI. Overlooking staff readiness can culminate in operational chaos and prolonged errors. But there’s more than meets the eye in mishaps of this nature.

Miscalculating machine compatibility with existing systems leads to integration headaches. A seamless fit is crucial, else productivity goals face severe setbacks. Mistakes as such frequently fly under the radar until it’s too late.

Quality assurance lapses could snowball into large-scale product recalls, tarnishing reputations overnight. Vigilant quality checks at all stages are non-negotiable in preserving brand integrity. But the chain reaction of pitfalls runs deeper still.

Inadequate support from suppliers during critical times can wreak havoc, especially if technical issues arise urgently. Establish relationships with aggressively supportive suppliers to shield operations from unanticipated delays. How can these pitfalls shape a strategy for resilience?

With advancements in AI, smart materials, and renewable energy, the landscape of packaging machines faces imminent revolution. Machines capable of packing variable product types without manual inputs could soon standardize operations. This foresight hints only at partial possibilities.

With sustainable, biodegradable materials gaining ground, future machines might incorporate compostable systems. This potentially reduces the ecological footprint of packaging across industries. As these innovations unfold, what's hidden beyond plain sight?

Artificial Intelligence promises more than just enhanced efficiency; it’s slated to usher in self-correcting systems that refine processes continuously, ensuring defect-free outputs. This probable future inspires discussions on extended capabilities.

Even though these notions sound futuristic, the impending evolution invites businesses today to adapt, upskill, and prepare. The sooner industries embrace these technologies, the better poised they are for future dominance. The closing notes provide an eye-opening perspective on this nearing era.

Pioneers in packaging technology share profound lessons about embracing change, leading with innovation, and sustaining relevance. Their journeys often highlight unconventional strategies that delivered outstanding results. Curious to uncover the wisdom they preach?

A vital lesson emphasizes embracing challenges as catalysts for invention. Regulatory hurdles that initially seem formidable often prompt innovations that yield long-term benefits. These audacious tactics set the trend for today’s advancements.

Furthermore, foresight in diversified automation safeguards against volatile economic environments, offering the flexibility to navigate both boom and bust cycles. Such resilience nurtures an unwavering market stance. What final revelation suggests itself here?

Ultimately, collaboration over competition affirms an evergreen lesson. Joining forces for mutual technological gains accelerates the roadmap towards greater achievements. With a peek at how innovators thrive, the final sections beckon a shift to action and reflection.

In the world of packaging machines, potential is limitless, yet understanding its depth and breadth dictates business success. The lessons and insights shared throughout this article position you at the cusp of informed decision-making. But, what resonates most profoundly is the adaptability to embrace change fearlessly.

Now, the baton is passed to you. Implement these strategies, capitalize on emerging trends, and sidestep pitfalls with confidence. Remember, packaging machines are not merely tools but instruments of growth and innovation. So why not join the conversation, share your experiences, and drive the dialogue further?

Excite others about the transformations reshaping industry landscapes, and let’s navigate this thrilling journey together. Ready to propel your operation to new heights? Share this article, enlighten others, and seize the future today!